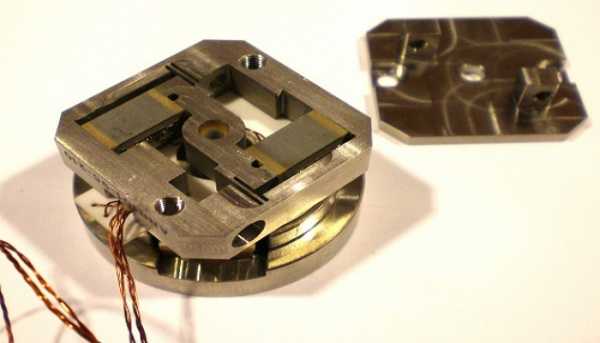

PiezoMotor can manufacture customised piezoelectric motors according to client requirements, by adding sensors, bearings and other attachments if required. The motors work without interfering with magnetic fields, which is critical in many advanced applications. The size of the motor is significantly reduced, and precision is gained by eliminating bulky and lashing mechanical parts. In addition, a conventional electric motor usually requires several assembled parts such as a rotor, stator, ball bearings, and linear screws to make it work. When traditional motor technologies fail to meet space or performance demands Piezo Motors are the perfect choice. The electronics required to drive and control Piezo LEGS motors are simple, compared with those normally required for conventional brushless electric and stepping motors.

T-Cube, K-Cube, and benchtop brushless, DC, stepper, and Piezo motor controllers). Other medical devices provided by the company include eye care instruments, analytical instruments, microscopes, precision liquid handling systems and valves. examples for Thorlabs motion control products (e.g. Both linear and rotary piezo motors are manufactured in non-magnetic materials. PiezoMotor can deliver fully non-magnetic motion solutions. There is a growing demand for robots within the medical field such as surgery or taking biopsies, which requires precision, and also working inside a magnetic field, which includes MRI scanners.Īnalytical instruments and precision liquid handling systems PI is a leading manufacturer of precision motion control and automation systems, hexapod 6-axis parallel robotic stages, air bearing motion systems, Gantry Systems, 3D printing, laser machining, and piezoelectric nano-positioning solutions.

0 kommentar(er)

0 kommentar(er)